TIG Welding 1/4" 6061 Aluminum Flat Bar Part 3 YouTube

This baby can TIG and stick weld, and even upgrades to a spool gun for MIG welding aluminum, mild steel, and stainless steel. Entry price on the Syncrowave 210 is $2,678. The 210's power supply is.

THE COMPLICATED WORLD OF ALUMINUM TIG WELDING AskForney

Vince from VC Metal Worx is switching gears from stainless and showing us how to strike an arc on some Aluminum.Pickup the TIG 200 LCD HERE: https://www.east.

TIG Welding Aluminum YouTube

5 tips for TIG welding aluminum 1. Clean everything scrupulously TIG welding aluminum requires that everything be squeaky clean, and this is particularly important with aluminum. Any trace of oil can cause porosity and may inhibit the flow of molten metal.

Aluminum TIG Welding Basics for Beginners How to TIG Weld Aluminum YouTube

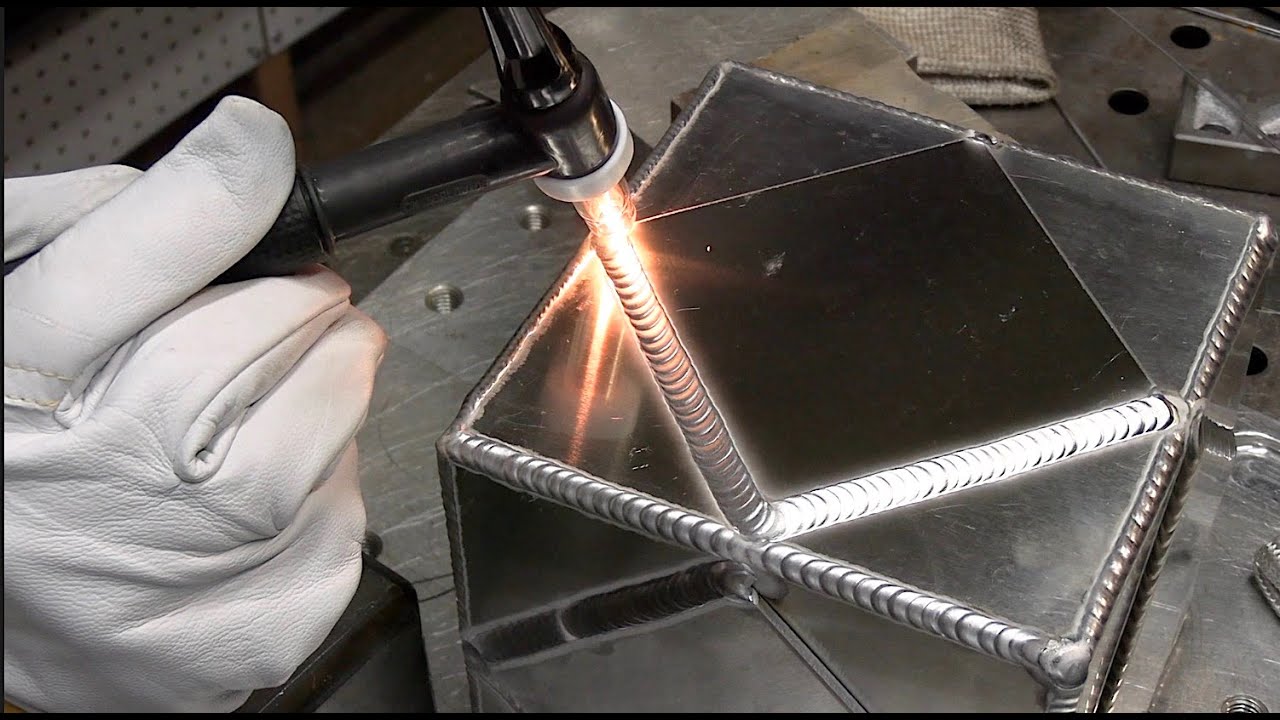

Tig welding, also known as gas tungsten arc welding (GTAW), is a welding process that uses a non-consumable tungsten electrode to produce the weld. A filler material is used to join the metal pieces together. The process is typically used for welding thin sections of aluminum, stainless steel, and other metals that require precise control over.

How To TIG Weld Aluminum A Beginner's Guide

Setting up the TIG welder for Aluminum will require you to go through the following steps: Choosing the Right Equipment (Right Type of TIG Welder) Selecting the Right Tungsten Electrode Cleaning the Aluminum Workpiece Choosing the Right Gas & Connecting the Gas Supply Adjusting the Amperage Adjusting the Alternating Current Balance Control

11 Tips for TIG Welding Aluminum with DC Welding Mastermind

TIG Welding Aluminum for Beginners Part 1: Positioning Watch on Step 2: Coordinate movement and filler deposition Next, you should work on the flow of your hand and torch movement without striking an arc. Practice with gloves on as you would in a normal welding situation.

How to TIG Weld Aluminum Without Filler Rod Welding Mastermind

Choosing the right tungsten for aluminum TIG welding By Frank Armao Updated May 18, 2023 November 5, 2014 Article Aluminum Welding Q: I am just getting into aluminum GTAW and I have heard many recommendations about which tungsten electrode I should use. Can you tell me how to make the right choice? A: I will certainly try.

How to TIG weld aluminum

TIG (GTAW) welding is one of the cleanest and best ways to weld aluminum. TIG welding allows maximum control over every aspect of the welding process, resulting in high-quality, clean weld beads that look amazing. The issue with TIG welding aluminum is that it can be daunting for beginner welders.

How To Tig Weld Aluminum Vertical commentsformeetings

Gas tungsten arc welding (GTAW) has traditionally been considered the go-to process for welding aluminum because of the high weld integrity and aesthetic appearance the process provides. Achieving high-quality welds—and getting the coveted stacked-dimes appearance—when welding aluminum with GTAW takes practice and skill.

Tig Welding Aluminum using Argon Helium Mix

V. Guidelines for TIG Welding Aluminum. Tungsten Selection: Use pure tungsten or a tungsten alloy suitable for aluminum welding. Thoriated, ceriated, or lanthanated tungsten alloys are commonly employed. Electrode Preparation: Ensure a sharp and clean electrode tip for optimal arc stability and better control over the weld pool.

Learning to TIG Weld Welding Aluminum YouTube

How To TIG Weld Aluminum - Beginners Guide to Getting Started Justin Voss 105K subscribers Join Subscribe Subscribed 4.6K 195K views 3 years ago #tigwelding #aluminumtigwelding #tigwelding.

Tig Welding Aluminum Tee 2f

Depending on which welder you are using, you may notice a few other adjustments we still need to cover, both pertinent to TIG welding aluminum. The first is balance. Balance refers to the negative and positive current percentages alternating between the electrode and your workpiece. A good starting point is 30% AC and 70% DC.

TIG Weld Aluminum Like A Pro [CKMT200 Master TIG] YouTube

0:00 / 24:04 Aluminum TIG Welding Basics for Beginners | How to TIG Weld Aluminum TimWelds 325K subscribers 101K views 2 years ago TIG Welding (Gas Tungsten Arc Welding - GTAW) A.

Getting Started with TIG Welding YesWelder

Besides the absence of flux or coated rods, welding in all positions is easy with the TIG process, because there is no slag to be cleaned. The thickness range of commonly welded aluminum materials by the TIG process is 0.040" (18 gauge) to 1/2" (1 -9.5 mm) for manual TIG welding and 0.025" (22 gauge) to 1-inch (0.25- 25 mm) for mechanized TIG welding such as orbital TIG Welding process.

7 Best TIG Welders for Aluminum Reviewed in Detail (Winter 2023)

"A dual-voltage TIG and Stick welder that features 10 - 200A output, 60% duty cycle and can cut aluminum up to 1/4" thick. 110/120V. capable of welding 7018 and 6013. inverter technology with pulse width modulation." Premium Pick: Lincoln Electric Square Wave TIG 200

TIG Welding Thin Aluminum Tee Joint Test TIG > Aluminum WelderSkills

The popularity of aluminum in automotive applications has brought TIG welding to a new golden age. Mechanically strong and visually appealing, TIG welding is the number one process chosen by professional welders for professional racing teams, and the avid auto enthusiast or hobbyist. That Confusing Thing About Aluminum